Description

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Material:

-

Stainless Steel

- Standard:

-

ANSI

- Place of Origin:

-

China

- Brand Name:

-

EP

- Product name:

-

Sprocket

- Processing:

-

Hobbing

- Heat treatment:

-

Hard Teeth

- Surface treatment:

-

Polishing

- Color:

-

Nature

- Pitch:

-

9.525 ~ 3801mm

- Size:

-

Customized Size

- Bore size:

-

as demands

- Bore Type:

-

Bore

- Service:

-

Drawing Custom

Selecting OND Sprockets

Please carefully examine the model and usage conditions of the chain that you will be using and select it.

Our sprocket is determined by the following elements:

|

1.Chain used

|

|||

|

OND sprocketes are manufactured with a tooth profile and dimensional precision to bring out the maximum performance of the chain you will use.

|

|

2. Number of teeth

|

|||

|

OND sprockets are available with small and large numbers of teeth to match your usage conditions.

|

Single pitch sprocket

*Chain matched:35 Teeth:from 9-120

*Chain matched:40 Teeth:from 9-120

*Chain matched:50 Teeth:from 9-120

*Chain matched:60 Teeth:from 9-120

*Chain matched:80 Teeth:from 9-120

*Chain matched:100 Teeth:from 9-120

*Chain matched:120 Teeth:from 9-120

*Chain matched:140 Teeth:from 9-120

*Chain matched:160 Teeth:from 9-120

*Chain matched:200 Teeth:from 9-120

Double pitch sprocket

*P=25.4mm Teeth:from 7-100

*P=31.8mm Teeth:from 7-100

*P=38.1mm Teeth:from 7-100

*P=50.8mm Teeth:from 7-100

*P=63.5mm Teeth:from 7-100

|

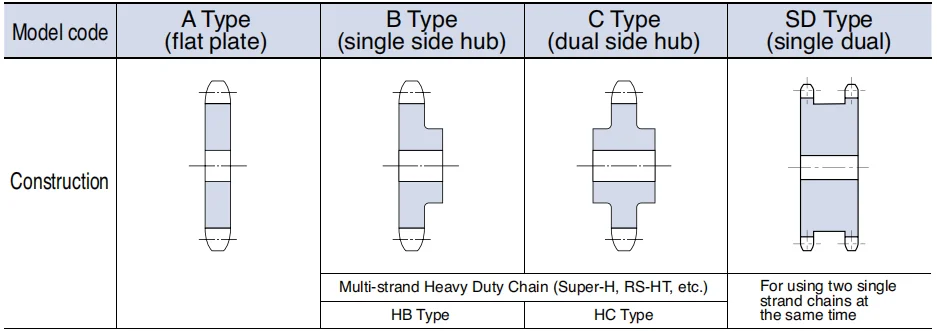

3. Consturction

|

|

4. Material

|

|||

|

Carbon Steel, Stainless Steel,Aluminum, Copper, Brass,42CrMo,40Cr,A3 and so on.

|

|

5. Bore

|

|||

|

Pilot bore, finished bore, taper bore and special bore

|

|

6. Treatment

|

|||

|

Heat Treatment

|

Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on.

|

||

|

Surface Treatment

|

Zinc Plating, Chrome plated, Black oxide Treatment, Spray Paint, Mirror Finish, Sand-blasting and so on.

|

||

Producing process

Blank forging—surface lathe doing—milling machine processing—hardening and quenching—inspect control–aspect making—package for sell.

Our Products Advantage

1. Every step from production order to the packing process has a strict quality inspection.

2. We have standard sprockets (DIN. ANSI. KANA); Non-standard sprockets (customized acording to customer drawings).

3. Export products with high quality and low price.

4.We have a good service before and after-sale.